Product Center

cat head tower crane 当前位置 :

当前位置 :

QTZ160(6516) tower crane

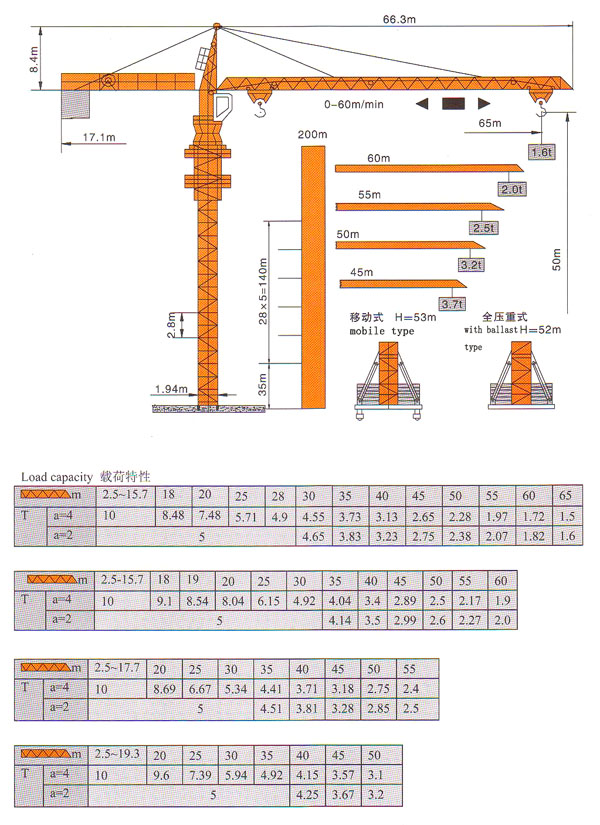

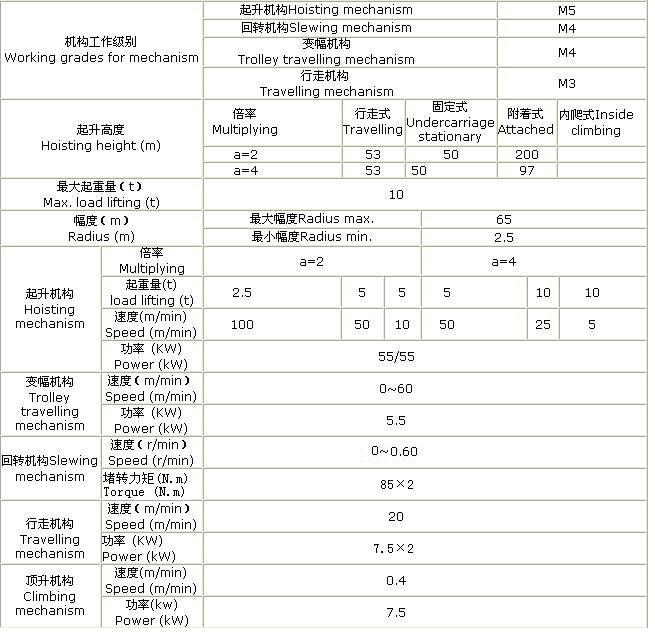

QTZ160 tower crane is to meet GB/T5031<< tower crane >> and GB5144<< tower crane safety regulations >> and other standard design of the reinforced tower crane, rated lifting moment 160t·m, the maximum lifting weight is 10 tons, TC6516, TC6020, TC5525, TC5032, TC4537 and other types. The machine speed regulating pole change motor hoist, slewing mechanism for variable frequency speed regulating mechanism, luffing mechanism planetary gear reducer internal drum, electric control system adopts imported components, security protection device for mechanical or electromechanical integration products, complete and reliable, the machine has a fixed, walk, adhesion, climbing and so on work type, can meet the city the high-level construction, industrial plant, power station dam, Bridges and other construction needs.

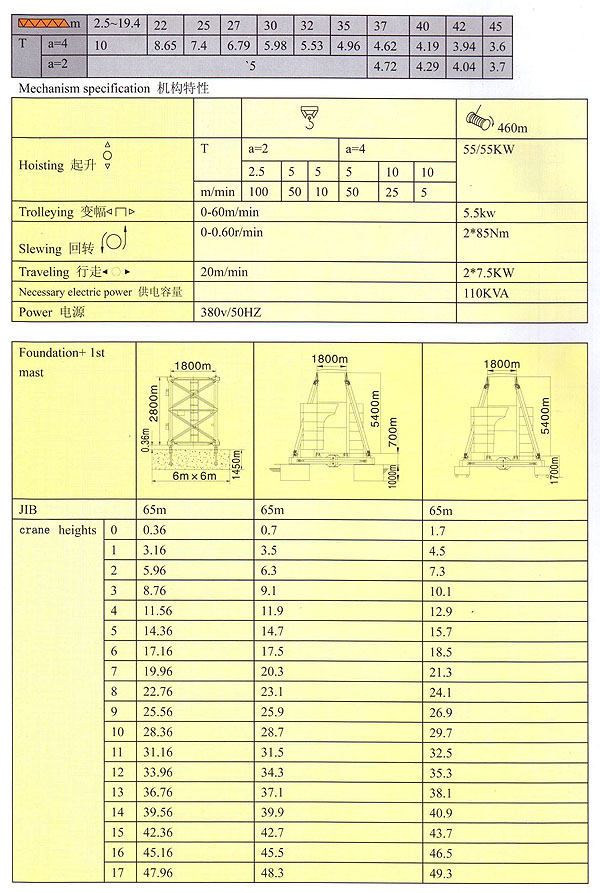

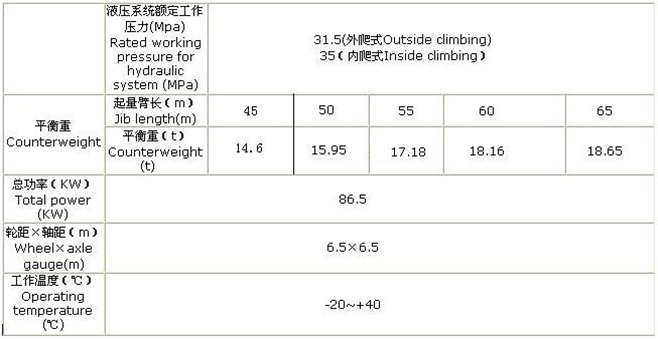

Technical parameters of QTZ160 (6516)

[lifting mechanism] :

The lifting mechanism (2600kg) adopts yzrswf280m-4/8-55/55kw two-speed motor, which drives the reduction box through the toothed coupling and then drives the drum. With stepless speed regulation, the minimum stable speed is less than 5 m/min, making the lifting and braking of goods stable. When using 2 ropes, the speed can reach 100m/min, 50m/min and 10m/min, and when using 4 ropes, the speed can reach 50m/min, 25m/min and 5m/min.

A normally closed hydraulic push rod brake (ywz3h315/90) is installed at the input shaft end of the reduction gear box (see figure 4-13). There is a height limiter on one side of the drum, which can be adjusted according to the required height. Reliable control, simple operation, easy maintenance.

[rotating mechanism] :

The rotary mechanism is a transmission device that provides power for the upper part of the tower crane. The device consists of a torque motor with a brake on the tail, a planetary reducer, a pinion and a rotary limiter. This tower machine adopts two sets of such devices, which are symmetrically distributed on both sides of the slewing bearing and mounted on the upper bearing, and the pinion gear meshes with the large tooth ring of the slewing bearing.

A disc brake with a normally open state at the input end of the reducer; Can be used for tower crane jacking and fixed point operation of the boom brake positioning.

The slewing limiter is used to control the tower crane to turn only 540° in one direction to avoid twisting the cable.

[luffing mechanism] :

The amplitude transformer (510Kg) mining motor yej132-4-5.5kw drives the drum through the planetary reducer, and enables the truck to run at three speeds of 0 ~ 60m/min on the derrick at high speed back and forth through the wire rope.

Motor tail with a regular closed brake, when the car motor power delay brake.

The amplitude limiter is used to prevent misoperation and stop the car before it hits the buffer at the base of the boom.

[tower body standard section] :

Local close-up of the main limb

The standard section of the tower body is a whole frame structure. The standard section is firmly connected with special high-strength bolts of 12-m36, and the bottom section is connected with high-strength bolts of 16-m36. Every three sections have a rest platform, the same specification of the standard section with interchangeability.

Lifting arm:

The lifting arm is divided into 11 sections. The upper chord of the third and eighth sections is provided with a lifting point of a tie rod, and the arms are connected by a pin shaft. The first arm is equipped with a trolley traction mechanism, and the arm end is equipped with a wire rope anti-twisting device. The maximum arm length is 65 meters, and it can be assembled into 4 arm lengths, such as 60 meters, 55 meters and 50 meters, to meet the needs of different rotating Spaces. A trolley luffing mechanism is installed in the root section of the boom and a platform frame is provided to facilitate installation and maintenance.

【 balance arm 】:

The balancing arm consists of two sections, one section of 8.175 m and one section of 8.865 m, connected by a pin shaft. With the help of the pin shaft, the balance arm and the balance arm tie rod are connected with the rotary tower body and the top of the tower into a whole

[rotary limiter] :

"The tower"

The top of the tower is an oblique cone. The upper end is connected with the lifting boom and the balancing boom by a pull rod to keep the two arms horizontal. The lower end is connected with the rotary tower by four pin shafts.

[bridge]

The cab is the workshop where the driver operates the tower crane, which is fixed on the right side of the rotary tower. Each indicator light and handle of the linkage control console are located on both sides of the driver's cab seat, which is easy to operate and has a broad field of vision.

The bridge electric cabinet is arranged in the rear of the bridge, main circuit breaker, lighting and auxiliary circuit breaker and other devices.

[weight limiter] :

[walking device] :

Walking mechanism has two active trolley, the active trolley is composed of motor, hydraulic coupling, worm gear reducer, disc brake, open gear and traveling wheel. The hydraulic coupler ensures the starting braking of the tower crane is stable and the walking speed is 20 meters/min.

The yz160m2-6-2 7.5kw ac motor controls the operation of the mechanism with the help of the main command controller. The normally closed disc brake at the end of the worm shaft is released when working, and the brake is delayed after shutdown and power failure. The delay time can be adjusted to ensure the short sliding distance of the stop and no shaking of the tower due to excessive braking.

Two travel switches are installed on the outside of the active trolley to control the tower crane to travel within the set limit position to ensure the safety of the tower crane.

[electronic control system and safety device] :

This system USES a programmable logic controller for central control, adopt the internationally used type of electric control system and low voltage electrical appliances imported electrical components, modular combination, rail style installation, the focus on two cross the main controller and the driver room button switch control, saves a lot of intermediate relay and time relay for logic control, adopting global procurement at the same time, using the international famous brand products, such as OMRON PLC (OMRON), Schneider contactor, thus greatly improve the reliability of the whole system, but also provides a convenient fault judgment positioning and eliminate. In addition, it also includes electrical safety devices such as anemometer, obstacle light, and mechanical safety devices such as trolley shaft breaking protection and traction rope breaking rope preventing slipping.